From haute couture to high-tech: Our journey to the automated series production of composite products began with the traditional St Gallen embroidery of the 19th century. Today we develop and produce innovative moulded parts using our unique stitching technology. Bionic. Made of carbon. Efficient lightweight construction, just like you find in nature.

2022

Expansion of the production area and production capacities:

- new 5-axis milling machine

- new RTM machine

2021

Move into new offices with an extension of the office space

2020

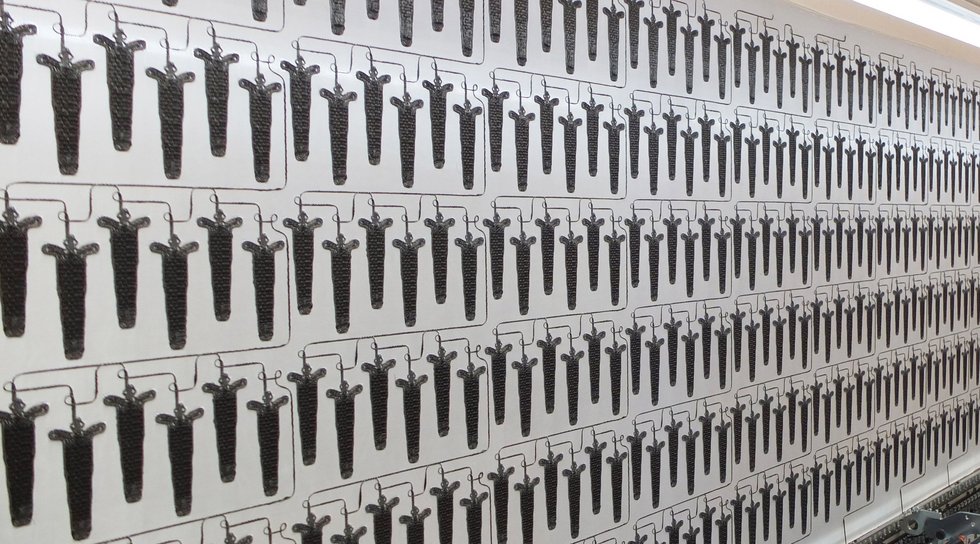

First deliveries of series production parts for the aviation industry

2019

- 10 year anniversary

- Significant expansion of the development department

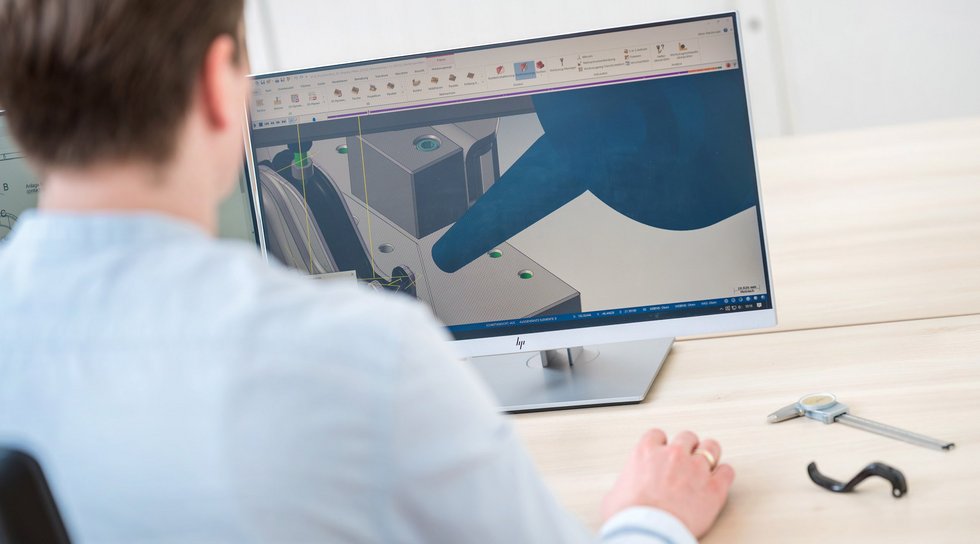

- Development of our own software for the design and optimisation of the fibre layout

- Investment in additional production machines

2018

- Start of production for the 4th generation brake lever

- Quality management system certified according to ISO 9001 (QM)

- Further automation of the RTM process

2016

- Development of bigger RTM systems to enable the production of larger parts

- Installation of a second large embroidery machine

2015

Implementation of a high-performance quality assurance system

2014

New development of a machine control system (with Pantec)

2011

- Further development of the stitching technology and focus on the RTM process

- Installation and commissioning of several systems and the 5-axis milling machine

2010

Start of series production for the 1st generation of the carbon brake lever

17.11.2009

- Founding of BIONTEC – Bionic Composite Technologies AG as a joint venture in St. Gallen

- Erika and Ueli Forster (embroidery), Martin Böhler (embroidery), Pantec (automation)

2007

Caroline and Emanuel Forster take over operational management of the Forster Group

2005

Martin Böhler starts the first stitching tests using carbon fibres

1992

- Various acquisitions in the textile industry over the years

- Merger of Forster Willi AG and Jacob Rohner AG to form Forster Rohner AG

1965

Peter, Ueli and Tobias Forster take over operational management

1904

Founding of Forster Willi & Co. by Conrad Forster-Willi

1863

Invention of the shuttle embroidery machine in St. Gallen by Isaak Gröbli